A new type of water cooled furnace thread smoke tube normal pressure boiler

Double grate burning, also known as water cooling grate, is a small boiler combustion mode with better smoke and dust removal.

The burning layer water-cooled grate on the air supply is from top to bottom (reverse combustion), the lower part of the auxiliary conventional water-cooled grate grate, half coal gas, the main combustion grate between two runs, fine particle layer on the fly with a not so as to achieve the purpose of burning, smoke and dust. When the water cooling grate cleaning the burning layer and falling ash, some dust will be taken out of the flue gas, but the time is shorter. China's vast territory, economic development is not balanced, not non important areas (suburbs, towns) coal-fired boiler to adopt advanced dust removal equipment, not used a large number of fuel gas boiler, therefore, small capacity water-cooled grate coal-fired boiler since 40 years ago in China's first research and development in Harbin, so far is still in use.

In addition, the heat intensity of the heated surface of the water cooled grate is quite high, and it can reduce the steel consumption of the boiler obviously with the heat transfer face of the high efficiency heat transfer pipe.

In the development process of industrial boiler in other countries, boiler capacity greater than 1 0.7MW is generally not used vertical structure, because although the floor area is small, the diameter and height of vertical pot shell are too large, resulting in obvious waste of steel. In particular, the water-cooling grate, such as furnace is arranged in the internal furnace, the shell has a larger diameter; such as grate is external, the advantages of smaller area no longer exists. In addition, the convection heating surface there are larger issues: safety and reliability of the tube plate vertical smoke pipe is not easy to guarantee (water side fouling difficult to remove); horizontal water pipe smoke speed is too low, it is difficult to prevent fouling, heat transfer effect is poor.

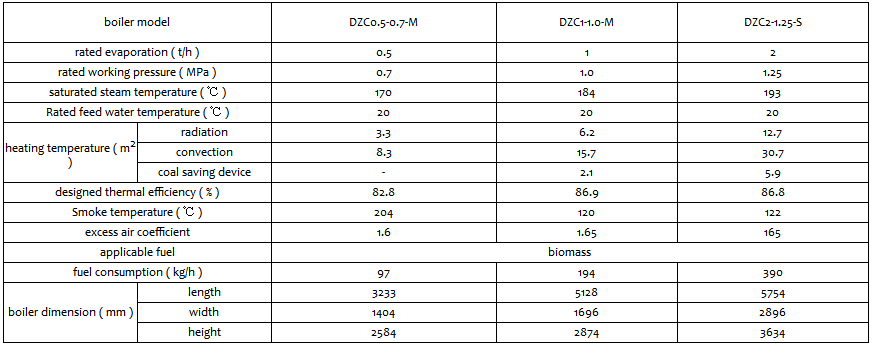

Based on the above reasons, the design of the 0.35MW - 2.1MW water-cooled grate pressure hot water boiler using a new type of fire has 28 years of experience of mature pipe horizontal boiler structure, combustion equipment for water cooling grate, to prevent smoke pipe entrance smoke temperature is too high a small water discharge pipe, boiler structure is compact, the overall factory (under the base).

The structure of boiler development to large capacity, but the water-cooled grate by hand burn, such as large capacity, the labor intensity of the workers is too large, which restricts further increase capacity.

The system is composed of a boiler backwater into unilateral water-cooled grate front header at the end of 3, by the end of the return pipe grate, the box to the rear by a water-cooled grate set after the water discharge pipe under the header, the water pipe enters the shell on both sides of the lower part by the header, followed by high temperature spray to the aqueduct at the bottom of the tube pipe pipe finally, the smoke tube from the top of the shell into the pipe.